I can never get sections to slide under the anti-roll plate on the cryostat. The sections always seem to bunch up on the edge of the anti-roll plate. What do I need to do to get it to work right?

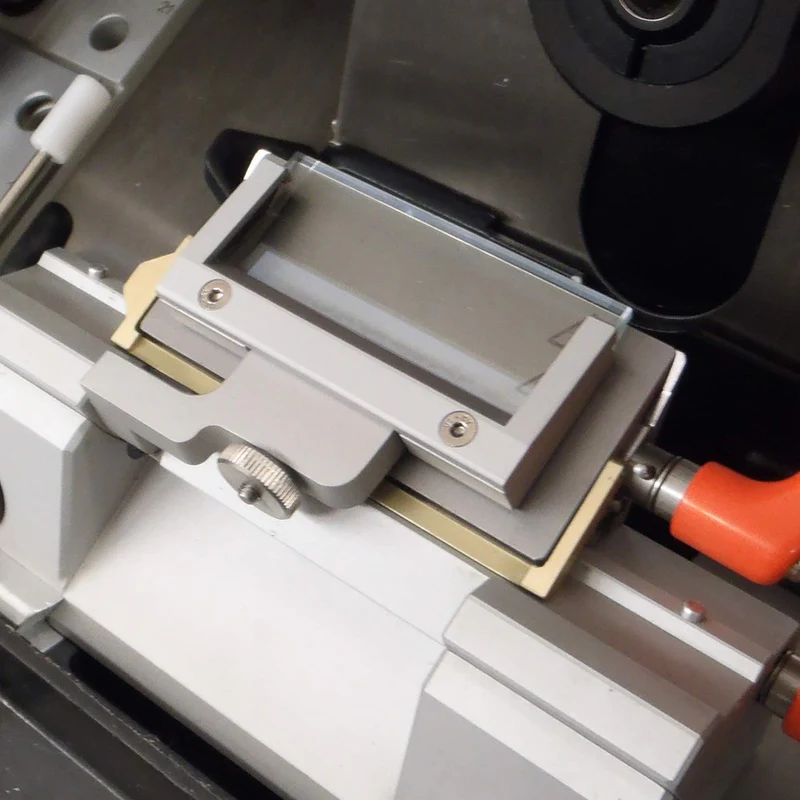

The anti-roll plate is a square or rectangle of plastic or glass that rests against the blade in the cryostat and allows the tissue to slide between the anti-roll plate and the knife. This allows for flatter sections, which can be picked up on the slide with fewer wrinkles IF the anti-roll plate is behaving properly.

In this article, we are going to discuss three common issues: thick sections, a jagged edge on an anti-roll plate, and the anti-roll plate position.

First, check to make sure the poor sections are not due to something else, such as a dull blade or a wrong clearance angle. If you can get a fairly good section without the anti-roll plate, then let’s look at three common problems that occur with the anti-roll plate.

Just so we know which side of the anti-roll plate I’m talking about, imagine a square (or rectangle) shape. The north side is touching the blade. The East and West sides are the vertical edges.

THICK SECTION:

The entire North length of the anti-roll plate does not lay flat against the blade. Only a couple of millimeters of the East and West sides are touching the blades. That is because the East and West sides are thicker. This allows the majority of the middle portion of the North side to be raised off the blade a fraction of a millimeter. This gap lets the section slide between the anti-roll plate and the blade but does not permit too much space to allow waviness of the section.

If you are cutting thick sections, they may be thicker than the gap between the plate and the blade. The section will jam up against the top of the anti-roll plate. To increase the gap thickness, wrap cellophane tape around the East and West edges, raising the middle section off the blade a fraction of a millimeter.

JAGGED EDGE OF ANTI-ROLL PLATE:

If the North edge of the anti-roll plate that is lying against the blade has been damaged by having something hit it, such as ice, something hard in the tissue, or being hit by the chuck that was not far enough back, then the anti-roll plate will have a jagged edge in a spot or two. This jagged spot or spots will grab the tissue, and snag it. Buy a new anti-roll plate and replace the old one or, try taking out the old one, and sanding the jagged edge on an Emory board, first the coarse side, and then the fine. Reattach the old anti-roll plate, and see if that sanding took care of the problem. Money saved!

Possibly what is causing the anti-roll plate’s north edge to be jagged is some debris on the edge, such as ice, old tissue, or frozen OCT. Wipe off the edge with cold gauze, so as not to heat up the plate with room-temperature gauze, if you were planning on sectioning right away. Remember to watch where your fingers are in relation to the knife edge. You might want to remove the blade while doing this step.

ANTI-ROLL PLATE POSITION:

The North edge of the anti-roll plate should be ¼ to ½ mm in front of the edge of the blade. It should look like the anti-roll plate is sticking out longer than the knife edge. Start with the anti-roll plate and the knife edge being parallel. Move the anti-roll plate up (out) a hair’s width. Try to obtain a section. If that doesn’t work, move the anti-roll plate up (out) another hair’s width. Keep advancing the plate and trying to get a section, until you get the correct distance. If the anti-roll plate is too far forward, the OCT block or chuck will hit the edge of the plate. If the plate isn’t quite forward enough, you won’t get a section under the plate. If the plate is too far down, the tissue will roll up on the edge of the anti-roll plate.

It’s like the baby bear in Goldilocks – it has to be just right.

Cryostats

Cryostats are used for sectioning fresh frozen tissue at cryogenic temperatures for cancer diagnostics or research. A cryostat will hold temperatures of -20 to -35 degrees celsius, and in some cases can cool a sample as low as -50 degrees celsius. A tissue sample is embedded in a tissue freezing medium on a ‘cryochuck’ (or specimen disc). Cryostats keep low temperatures with a refrigeration system that utilizes a compressor.

A cryostat is a type of laboratory instrument that is used to cut very thin slices (typically less than 20 micrometers thick) of biological tissue samples. It is called a “cryostat” because it is designed to cut tissues at very low temperatures, typically in the range of -20 to -40 degrees Celsius.

Cryostats work by freezing the tissue samples in a cryogen such as liquid nitrogen or dry ice, and then using a specialized microtome (a device used to cut thin slices of tissue) to cut the frozen tissue into thin slices. The frozen tissue is more brittle and easier to cut than unfrozen tissue, which allows for the production of very thin, uniform slices.

Cryostats are commonly used in research and medical settings to study the structure and function of tissues at the microscopic level. They are an essential tool in the field of histology, which is the study of tissues at the microscopic level, and are used to prepare tissue samples for a wide range of applications, including diagnosing diseases, studying the effects of drugs on tissues, and researching the structure and function of tissues.

Cryostats are also used in a variety of other applications, including the production of very thin slices of materials such as metals and ceramics for use in electron microscopy and other types of materials analysis.

Rankin supplies both new and professionally refurbished cryostats, reconditioned back to OEM specification. We reset the lifespan on used cryostats through our remanufacturing process with trained biomedical technicians.