The histology laboratory is a dangerous place to work for employees. Sharp knives, slick floors, hazardous chemicals and bloodborne pathogens are just the main sources of potential accidents. A way to keep histology laboratory employees safe is to provide information on dangers, explain the ways in which employees can protect themselves, and provide annual training to reinforce this information. This is not just a good plan. In most instances, this plan is backed by laws and regulations. This current series of blogs will delve into the various regulations, and how laboratories need to be in compliance in order to keep employees safe.

OSHA – The Formaldehyde Standard

Passed in December 1987, the standard protects all workers, laboratory and industry alike. The standard was revised in May 1992 to incorporate lower exposure limits. Copies of the standard can be obtained from your local OSHA office, or on line.

OSHA uses different types of limits for airborne exposures, which reflect Permissible Exposure Limits (PEL).

Time Weighted Average (TWA) is the airborne concentration averaged over eight consecutive hours. The TWA for formaldehyde is 0.75 ppm. No employee may be exposed to more than 0.75 ppm of formaldehyde over eight hours.

Short Term Exposure Limit (STEL) is the airborne concentration averaged over the worst 15 minutes. The STEL for formaldehyde is 2 ppm.

OSHA has also set an Action Level for formaldehyde of 0.5 ppm averaged over 8 hours. If this limit is reached or exceeded, the employee must be notified and steps taken immediately to adjust procedures that result in a decrease of the airborne concentration.

Employee monitoring is required to document the exposures existing in the laboratory. Initial monitoring of each exposed employee is required, unless monitoring has been done previously for a particular job description. Initial monitoring must be repeated if there is a change in work procedures or control systems. If an employee displays any exposure symptoms (i.e. respiratory, dermal, etc.) the employee must be monitored immediately.

If either the TWA or STEL is exceeded, the employer can:

- Install engineering controls, such as increased ventilation.

- Change work practice controls, such as procedural changes.

- Provide and require use of respirators.

Periodic employee monitoring depends on the initial monitoring results.

- If exposure levels are at or above the Action Level of 0.5 ppm, immediate monitoring must be done for each employee or job description and continued until the issue is resolved.

- If the STEL is exceeded, immediate monitoring must occur and continue until the issue is resolved.

Periodic monitoring may be discontinued if two successive samples taken at least seven days apart are below the Action Level and STEL.

Recommendation: In our laboratory, we monitor employees annually, even though the standard does not require it. We feel it is important for both employer and employee to make certain the work environment is safe for everyone.

Required: Safety goggles, gloves and an impervious gown, as well as access to an eyewash station and safety shower are required when handling formalin, regardless of the exposure limit (Figure 1).

Remember:

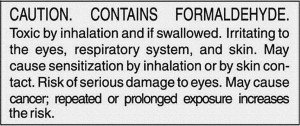

The above label must be present on EVERY container and specimen bottle of formaldehyde. It is there for a reason. Formaldehyde is a POISON and CARCINOGEN. You must handle it with proper personal protective equipment (PPE) using a ventilated work station…always…without exception.

Histology laboratory personnel who change out tissue processors are especially prone to formaldehyde liquid and vapor exposure. Personnel must wear the PPE described above while handling formaldehyde. Additionally, when pouring containers of formaldehyde (i.e. from on board tissue processors, into waste containers), employees should be performing this function in a fume hood to prevent exposure. Alternatively, employees may be fit-tested for a respirator to wear during the handling of formaldehyde. Goggles, rather than safety glasses, are the eye protection of choice, since they protect against splashes and vapors (Figure 2).

References

- Theory and Practice of Histological Techniques. Chapter 10. JD Bancroft, A Stevens ed. Churchill Livingstone, NY. Fourth edition. 1996

- Theory and Practice of Histotechnology. Chapter 9. DC Sheehan, BB Hrapchak. CV Mosby Company, St. Louis. First edition. 1980.

- CM Chapman. Histology Study Group. Presented at Region I meeting, hosted by MaSH. 2014.

- Laboratory Safety. NSH Self Assessment Booklet. 1st page 33, 2004.]

- Hazardous Materials in the Histopathology Laboratory. Dapson and Dapson. Fourth Edition. Anatech Ltd.